Warehouse automation is a solution to efficiency challenges that would be impossible with traditional systems. It is distinguished by features such as innovative operational logic and fully automated order management for fulfillment. These values were recognized by one of our e-commerce customers. In the article you will read what the customer's problem was and learn what proposal we worked out together. Perhaps you too are facing such difficulties?

The customer's need

The latest project proposal we worked on was the implementation of a warehouse for a company that sells furniture and home furnishings. An increase in the number of orders placed turned into a need to automate the warehouse. The client wants the solution to be hybrid, so that the warehouse system "grows" as the assortment of offered products increases. Knowing the customer's problem, we proposed the solution described below.

Project of an automated warehouse

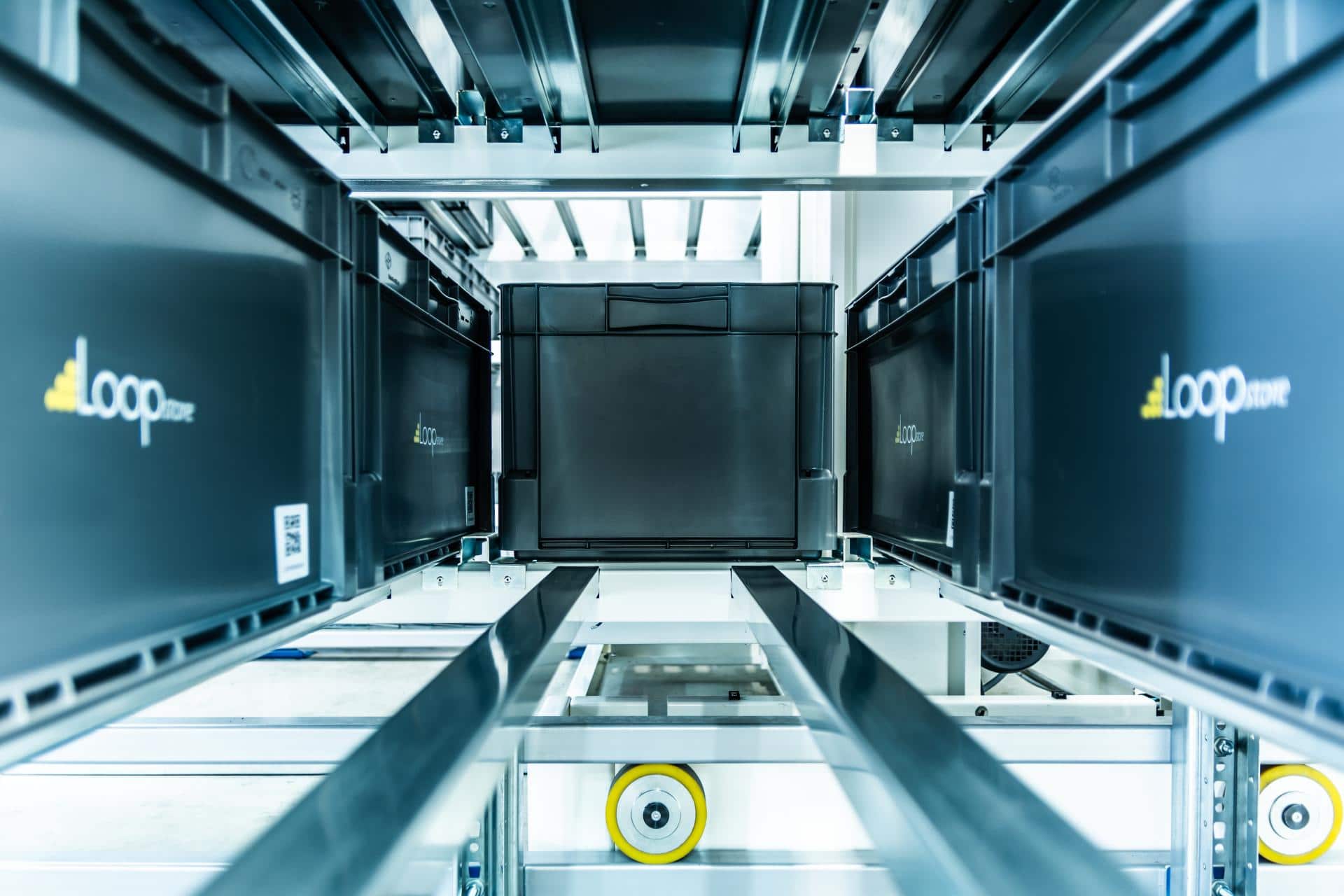

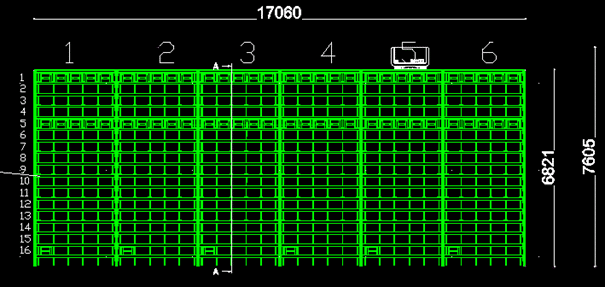

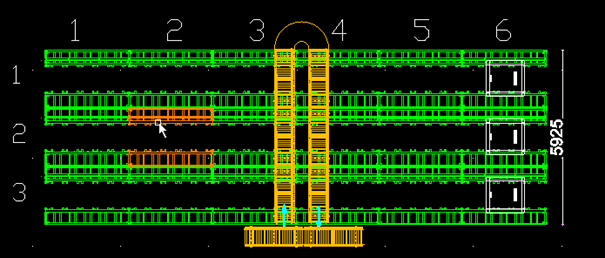

The proposed system can handle 2,900 containers of 600x400x320 mm. The installation has small dimensions: length 17 m, width 6 m and height 8 m. Below is a front and top view of the project of the automated storage system.

Automation process

The client already has a packing area, so our proposal is limited to building an automatic high storage system, i.e. installing racks and robots and attaching a section that feeds and receives boxes from the sorter. These boxes will be distributed by the sorter to the picking stations and collected from these stations. The capacity of such a system is more than 200 lines per hour.

Perspektywa dalszego rozwoju magazynu

A huge advantage of the presented proposal is the possibility of increasing the efficiency of warehouse processes by adding one robot per path. In such a scheme, it is possible to achieve efficiency of even more than 380 lines per hour.

The customer will also be able to increase the capacity of the warehouse by lengthening the paths. Productivity will be slightly lower. The investment outlay will be significantly reduced, as already installed robots will be used. The additional cost will then be only racking and software changes.

Cooperation with LoopStore

Deciding to cooperate with us, the customer receives a flexible system that adapts to the current solutions they have. We open up the possibility of expanding the warehouse in many areas and at a reasonable cost.

Recent Comments