Components of the automated warehouse in Merida

As part of the automation of the central warehouse, the following were used:

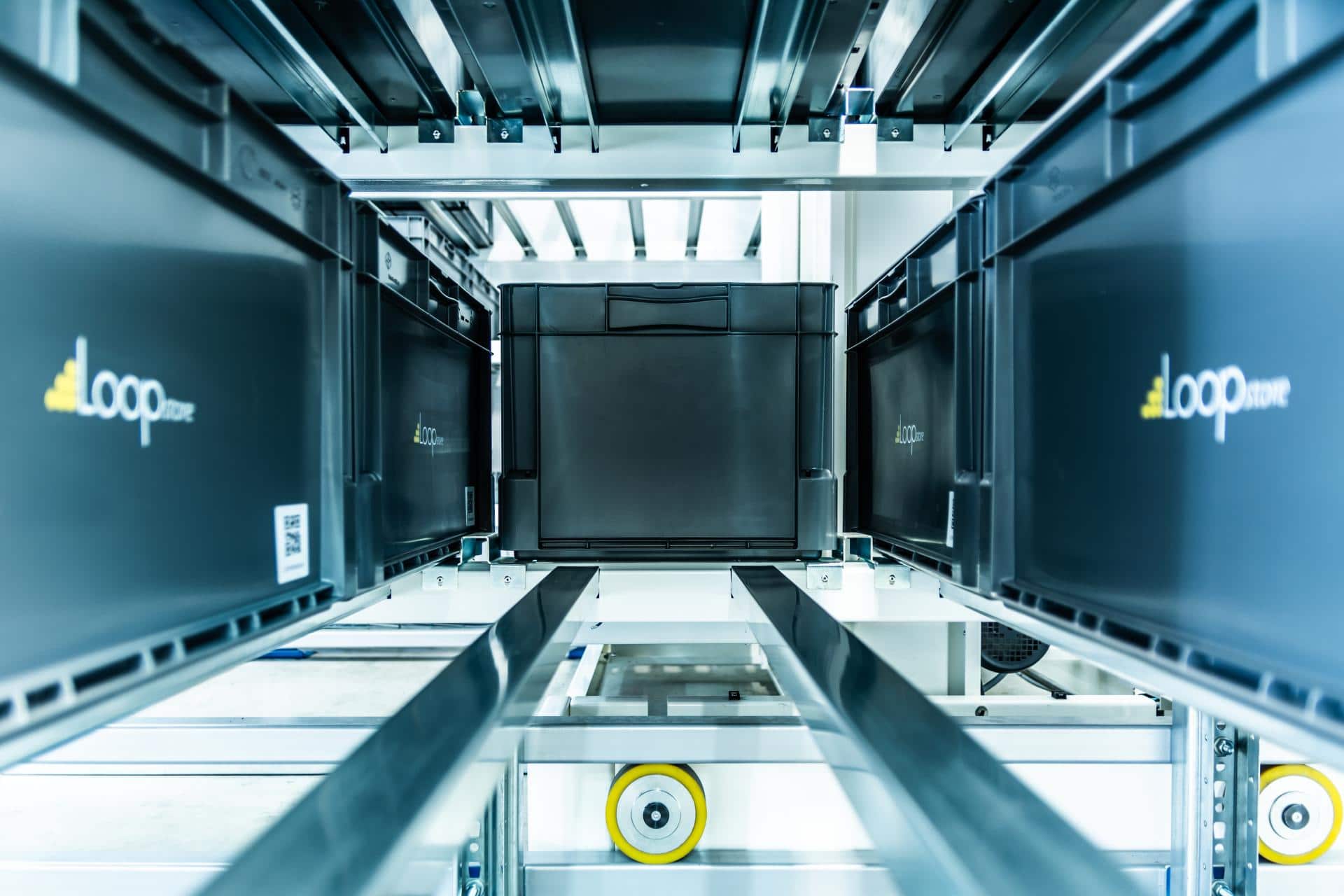

- A storage rack 16 m long, 8 m high and 2 m deep, for 700 boxes with dimensions 400x600x320 mm;

- Automated robot BOxSS;

- GTM (Goods to Man) station;

- Transport section for buffering containers - integrated with the warehouse space.

The automation used: BOxSS system

The BOxSS is an ASRS (Automated Storage and Retrieval System) automated product storage and retrieval system that enabled the handling of goods stored in containers. This autonomous robot is radio-controlled and located on top of the warehouse. It is equipped with a gripper that can lower itself along the entire rack to select a specific container. This allows access to any location in the warehouse.

Operation of the storage system

The warehouse system is operated using an integrated BMS (building management system) software that communicates with the customer's WMS (warehouse management software) to exchange data on orders, picks and warehouse status. The BMS can also operate independently of the WMS, meaning that the operator can enter orders and retrieve the desired products himself.

The BOxSS system allows for goods management, prioritization, optimization of stored stocks and automatic placement of products depending on their rotation.

With the help of an operator station, the system allows the picking and replenishment of stocks, and only one person is required for operation.

The system for the Merida logistics center was designed so that the containers move only inside the system, which allows for their full control and prevents damage or mistakes.

Technical parameters of the implementation

| Power | 2,65 [kW] |

|

Supply voltage / network type |

400 VAC TN-S |

|

Control voltage |

24 [V] DC |

|

Overcurrent protection |

16 [A] |

|

Capacity |

650 containers (600x400x320 mm) |

|

Efficiency |

60 [s/container] |

|

The capacity of roll buffer |

4 [containers] |

|

Maximum load |

25 [kg/container] |

|

Dimensions of handled containers |

600x400x320 [mm] (nr 8312000C50-002) 600x400x220 [mm] 600x400x120 [mm] |

|

Overall dimensions |

width = 3 [m] length = 18 [m] height = 8 [m] |

|

Type of operation |

Automatic |

Benefits of the implementation of an automatic warehouse in Merida logistics center

- Reduction of storage space for goods with small dimensions;

- Direct access to goods from one place (GTM station);

- Accelerated picking (while the warehouse brings the containers to the buffer, the operator collects the bulky items stored in the standard way, then drives to the station and pulls the goods out of the boxes one by one, without waiting until the robot brings them in);

- Generating online reports, e.g. about the state of the warehouse (inventory), shortages or low stock, etc;

Does your warehouse also require automation? Feel free to contact us!

Project carried out together with Nedcon Silesia.

Recent Comments