The growth of online sales and changing production solutions have contributed to the increased demand for warehouse space. Specialized warehouses and logistics centers began to emerge. Solutions that were once used are starting to be replaced by newer technologies, contributing to the development of warehouse automation.

Automated warehouse - definition and stages

An automated warehouse is a fairly general term - it can refer to warehouses in which virtually all the work is done by machines, as well as those in which some tasks are carried out using robots. It is assumed that an automated warehouse, is one in which logistical processes have been optimized using automatically controlled devices.

There are three basic stages in the automation of goods storage facilities.

1. Low level of automation

In this stage, facilities use traditional storage and product handling methods. Workers are employed to perform their tasks using dedicated equipment. The operational and decision-making process is purely manpower-driven.

2. Medium level of automation

This stage is characterized by the introduction of a Warehouse Management System (WMS), i.e. a warehouse information system. There is also a partial transfer of duties from people to machines.

3. High level of automation

In warehouses with a high level of automation, most tasks and operations are performed by machines and equipment designed for this purpose. They are controlled with the help of appropriate software.

Automation in a warehouse - facts and myths

There are many theories about the automation of facilities (not only those in warehouses). Many of them are myths resulting from a lack of knowledge, some of them are a result of a reluctance to change, and some of them are just a habit.

The first theory, the most common one, which is often crucial in the decision to introduce warehouse automation, is the skyrocketing cost of its implementation. There is no denying that the total automation of storage facilities is expensive. Consider your business growth projections, the current cost of maintaining your current infrastructure, and weigh that against the cost of your processes, equipment, and machinery. It is not always necessary to implement complete automation. Even the implementation of several solutions may be associated with a significant increase in the efficiency and smoothness of warehouse operations.

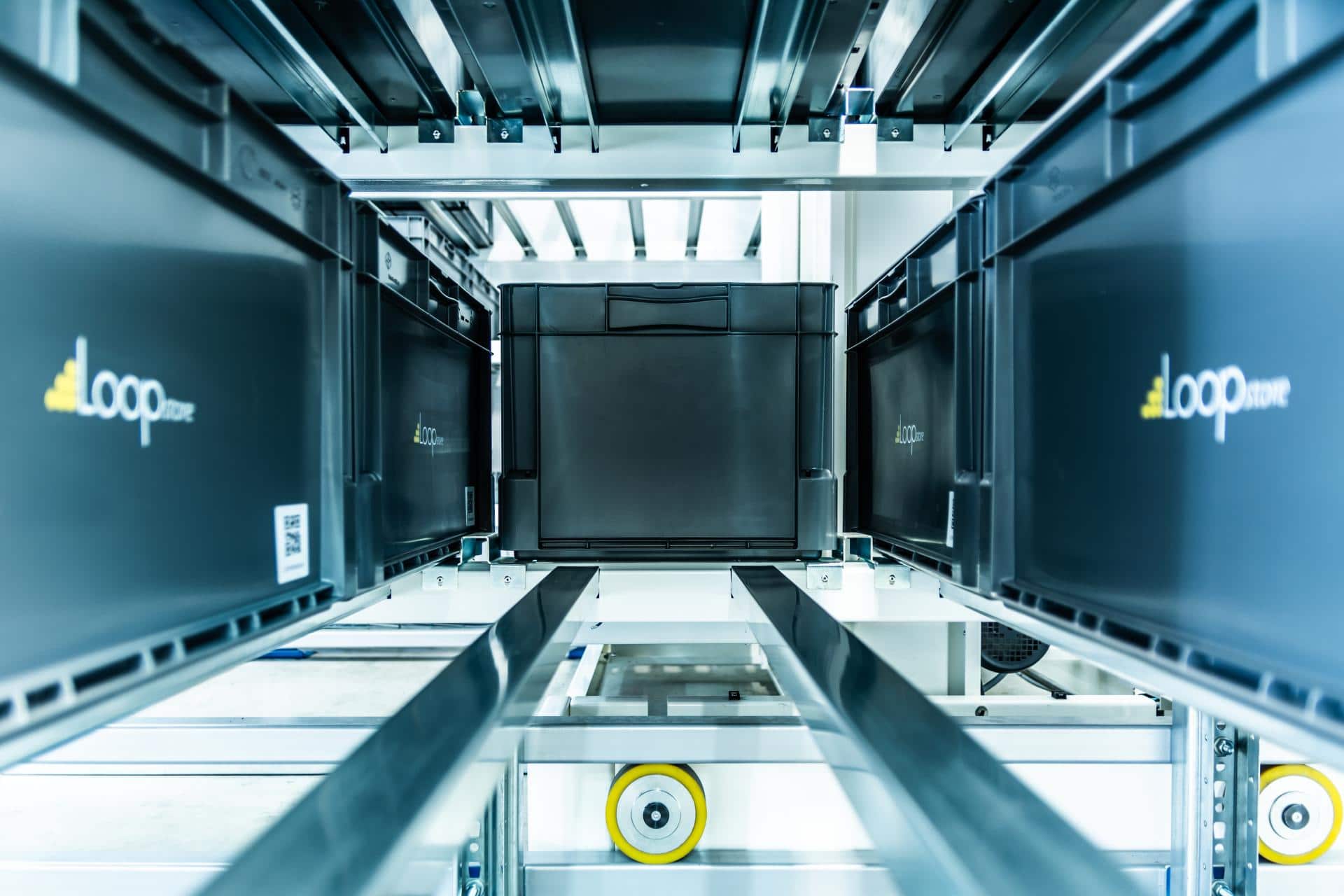

The issue of space is also worth considering. It will not always be possible to buy more space on which to build another warehouse hall. This is conditioned not only by the lower availability of land but also by the increasingly higher cost of purchase. Warehouse scaling seems to be a perfect solution - that is why the BOxSS system was created.

Another theory that is closely related to automation is that all workers will lose their jobs because they will be replaced by robots. This is a myth. Yes, the introduction of modern technology allows the transfer of duties from people to machines, but employees will be needed in other areas, such as quality control, supervision of the equipment, or maintenance.

There will be a need to reorganize structures, but this will not result in handing in the notice of termination to all warehouse workers. In addition, work on the warehouse floor increasingly requires process control. These tasks are tedious and physically demanding for employees. Converting them into automated ones will make daily work more ergonomic.

There are fewer and fewer workers available on the labor market at an increasing cost of labor. This is another argument to decide to scale your warehouse.

Finally, the thing about the operation - automated warehouses can work around the clock. This is both a fact and a myth. The capacity of a warehouse depends on the degree of its automation. If all processes are handled solely by machines, then indeed, the warehouse can operate around the clock. The same is true for places, even those not fully automated, where the staff is employed in shifts - then the legislation does not prohibit round-the-clock work.

Is it necessary to automate the warehouse?

As previously mentioned, the progressive development of trade and industry around the world, in a way, forces progress in the area of storage. Tens of thousands of goods, which daily pass through the centers, are sometimes even impossible to handle by human hands.

Automation aims to improve efficiency, speed and effectiveness. Its implementation contributes to the safety and continuity of warehouse operations. The most important element of the technology of automated storage processes is precision and repeatability.

Another reason to implement a warehouse automation procedure may be safety. It is primarily about the safety of employees, but also about the goods. If despite reliable compliance with health and safety rules, accidents in the warehouse occur more and more often, you should consider starting to automate the processes. An analogy should be made with damage to goods, especially if losses resulting from damage to stored goods are significant.

It is difficult to unequivocally assess at what point in a company's development warehouse automation is necessary. To reliably answer this question, it is necessary to know the characteristics of the warehouse, the structure of the facility and financial capabilities. As the company associated with the storage of goods grows, the scaling of automation can also be applied.

By choosing to work with LoopStore, you are assured that your automated warehouse will be adapted to the growth of your business and, where possible, scaled up. The BOxSS system can be easily expanded by adding more warehouse racks, without interfering with day-to-day operations and ultimately increasing the efficiency of your business.

If you have any questions - contact us!